Once all the rotten stuff was removed, we let it dry out for a day while Jim cut supports. This one under the doorway runs almost to the outer hulls. There will be 3 more just like it.

One down, 2 more to go.

Each one is smaller than the one before it so Jim is able to use the same template by cutting it to size.

They should give enough support for the 3/4 marine plywood that will be on top of them, and allow water to flow under them to the bilge pump and have some air flow between and under the plywood.

Getting them just right.

Each stringer will have 2 1”x4”s on them, cut so they are the same height as the fiberglass edge to help spread the weight.

After all the stingers were in place, Jim caulked around the edge of the fiberglass. We then set the 3/4” plywood in place, caulked around the edge again, let it dry and Jim painted it.

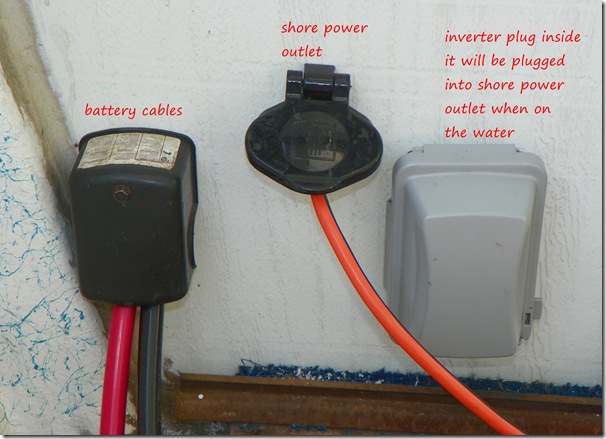

Once the paint is dry, he can start installing the “house” battery box and the starting battery, find a spot for the generator and extended run tank and fuel tanks.

The square “hole” is a well for the bilge pump.

The next big project will be installing the 15 gallon fresh water tank, the 2 1/2 gallon water heater, the faucet and water pump, the “out door” shower and the microwave and new cabinet doors.

Looks like it will be a few more weeks before we get on the water.